What Laser to Choose to Process Leather?

Before purchasing a laser, determine the items it will perform.

For smaller items such as wallets, watch straps, document organizers or cell phone cases with a working area of 20 x 30 cm a Laserpecker 4 handheld laser engraver is sufficient. This laser engraver is capable of engraving and cutting at a very high speed.

https://www.htpow.net/sculpfun....-s10-10w-laser-engra

https://www.htpow.net/sculpfun

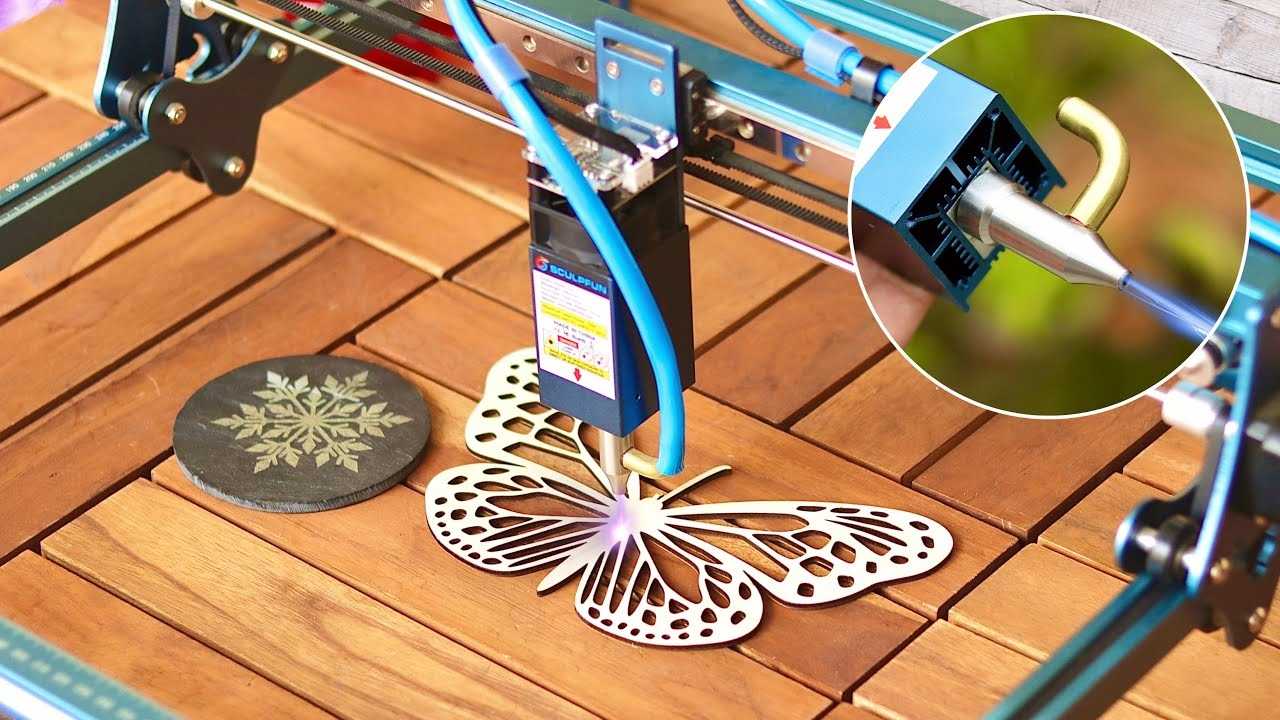

For larger items, you need a laser with a large enough working area. To cut leather for garment making, you need a working area of at least 40 x 40 cm. In this case, the right solution is the Sculpfun S10 laser engraver. With the diode laser, you can easily engrave or cut leather products.

https://www.htpow.net/laserpec....ker-4-dual-laser-eng

https://www.htpow.net/laser-engraving-machine

Wallet Engraving

There is no doubt that any craftsman would like to create high quality patterns for their products, easily cutting intricate patterns and small details in leather without damaging the material. The Sculpfun S30 Pro Max laser engraver will help you in your work.

https://www.htpow.net/sculpfun-s30-pro-max-20w-laser-engraver

For practical and high quality leather cutting, Sculpfun recommends diode lasers with an output power of 10 W or higher, approximately 10-20 W laser power output. Using a higher power laser will significantly reduce the cutting or engraving time and allow thicker samples to be cut.

Laser cutters/engravers are simple and easy to use. With a laser engraver, you can engrave finished products or workpieces. For this, you do not need additional technical knowledge or special skills. You simply create a file with a template or sketch in the graphic editor and load it into the laser engraver's work program.

Leather Laser Engraving Tips

Laser engraving on leather is a great way to add personality to your projects. Here are some tips to help you get the perfect laser engraving design on leather.

Choose the right laser for the job: If you are working with thin leather, you will need a laser that can produce a very fine beam. For thicker leathers, you need a laser with more power.

Use the right settings: The speed and power of the laser will have a major impact on the outcome of your design. Try different settings until you find the one that works best for your project.

Be careful not to overdo it: It's easy to accidentally burn through leather if you're not careful. If you are unsure, proceed with caution and take your time.

Test on a scrap piece of leather first: It is a good idea to test your design on a scrap piece of leather before laser engraving your final project. This will help you avoid any surprises later.

Keep your design simple: The more complex the design, the more difficult laser engraving will be. If you are just starting out, stick to simple shapes and lines.

Use laser-friendly leather: Some types of leather are better suited for laser engraving than others. Do some research to find the right leather for your laser.

Prepare your leather properly: It is important to clean and prepare your leather before you start laser engraving. This will help ensure that your design looks its best.

Mark your lines clearly: Make sure your lines are clearly marked on the leather. This will help you stay on track.

There are many different types of laser cutting and engraving machines on the market, so it is important to choose the one that suits your needs.If you need to purchase a laser engraving machine, you can go to the HTPOW website to purchase,HTPOW has cooperated with almost laser engraving and cutting machine brands and has become the world's largest supplier of home laser engraving machines.