The Use of Laser Engraving Machine

The application of laser engraving is more frequently used in industry and households now, and more and more people like to personalize their own items. Therefore, there are many laser engraving machine manufacturers and laser engraving machine brands, among which the better brands are Ortur, LaserPecker, Atomstack, Sculpfun and xTool.

With so many laser engraving machine usage scenarios, there will definitely be many people who want to know what the principles of laser engraving and laser cutting are, and introduce the use of Ortur Laser Master 3 to you.

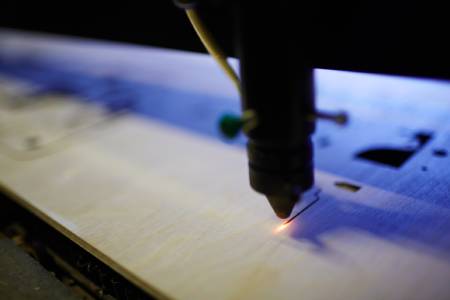

Principle of Laser Engraving Machine

Laser engraver work by directing the output of a high-power laser, most commonly through optics. The laser beam itself is a beam of high-intensity light.

For CO2 lasers, the single wavelength is in the infrared part of the spectrum, invisible to the human eye. The beam itself, which is only about 3/4 of an inch in diameter, propagates from the laser resonator, creating the beam through the machine's beam path. It bounces off of a mirror or more technically called a beam bender in different directions, ultimately focusing on the material you want to cut. The focused laser beam is passed through a nozzle that also passes through a compressed gas such as oxygen or nitrogen. The laser beam is focused by a special lens or curved mirror at the cutting head. Once the beam is precisely focused on a point, the heat density at that point increases to an extreme level. Similar to the concept of using a magnifying glass to focus the sun's rays onto an object to start a fire. The word "laser" has a neat acronym, and five words are easier to define; light amplification by stimulated emission of radiation.

How to Own Your Own Laser Engraver

This process is so accurate and efficient that it has become a necessity for many businesses. Laser engraving cutting is a stable, reliable and very precise cutting process that can save you time and money while increasing productivity. At HTPOW, each of our UK CO2 laser cutters is designed to cleanly cut a wide range of organic materials including cloth, card, wood, plywood, leather, laminate, plastic, TPE and many others. In addition to CO2 machines, HTPOW also offers a rapidly expanding range of lasers and engraving machines made by all well-known brands, including metal cutters and microsteppers. We also offer advice, so if you're not sure which machine is right for you, or would like a more detailed look at the benefits of each, we'd be happy to help.

HTPOW also lists various materials that are compatible with the machine, if the material is not listed, simply utilize the "Send a Sample" service for any professional material to get expert advice. Find out more about us and how we can help you on the HTPOW website.