On the very cheap end will get a large cardboard box to cover the laser while it is running. This will keep all the smoke out, and if you're feeling fancy you can even add a cheap exhaust fan with some flexible ducting to get the smoke out the next window. However, there are of course some safety concerns with using highly flammable cardboard around a laser cutter and the inability to observe progress.

This brings me to the next step, and the options I actually recommend. For some visibility, you can add a tinted acrylic window that blocks the laser but still lets you see inside. To deal with the smoke, we'll use a cheap exhaust fan and some flexible ducting. This will result in a very functional case that is still very easy to build and not too expensive.

Because every laser engraver is a slightly different size, it won't do you much good if I just tell you the size I used for the machine and leave it there. Instead, I'll show you how to find the right size yourself.

To get the width of our enclosure, we want to see where the widest part of our machine is. Also, keep in mind that things like cables sticking out may need some space to move smoothly. Then you'll add some extra margin, like 1/2 inch or 10mm.

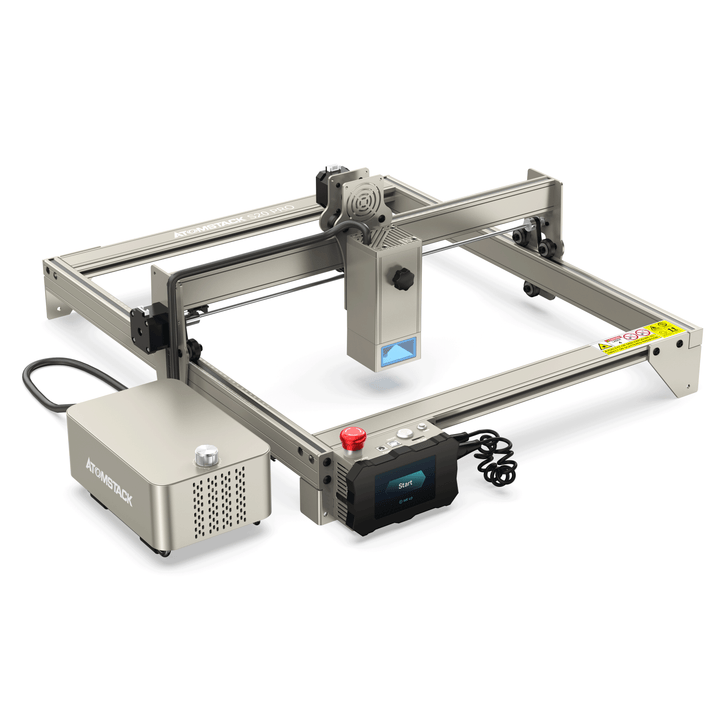

The dust cover for the ATOMSTACK B1 Enclosure laser engraver is equipped with an air inlet and a ventilation fan. The fumes from engraving or cutting will be purified through the filter system and exhaust, creating a fresh working environment for you.

B1 laser cutting machine shell safe design, fireproof metal structure, make the laser machine work safer, acrylic window design can filter laser to protect eyes and make viewing more convenient.

ATOMSTACK laser engraving machine shell safety dust box design, all metal structure, more durable, fireproof and dustproof.

The protective box cover with large internal space, and the bottom of the box has a movable bottom plate, which can be disassembled and can be placed with rollers to meet your needs. It is convenient for you to clean up the waste generated after engraving or cutting.

Ventilation system design Powerful ventilation system, high smoke removal efficiency, all-metal structure design, effective dustproof and fireproof, making your art carving work safer and more secure Automatic exhaust comes with an air outlet of about 2 meters, which can be opened after opening Automatic start of exhaust work, duct exhaust or use with air purifier for more comfortable working environment More flexible use Bottom removable door for placing rollers Engraving cylindrical objects, making it easier for you to clean up scraps after engraving and cutting work Compatible with all Atomstack machines Compatible with A5 series, S series, X series, P series and 95% of similar volume engraving machine brands on the market 670mm 300mm.

No matter what laser engraver you have, with very few exceptions, they all have one big problem in common, they are not closed. While this doesn't really matter for a 3D printer where you just need an enclosure to print special materials, for a laser it's a must. Carving or cutting anything creates a lot of smoke, and if you don't deal with it, it will just fill up your room. You can run the laser outside or next to a large window, but it's not a great long-term solution, especially during the colder months. Additionally, running an open frame laser engraver poses a hazard to any other person or pet who enters the room without proper safety equipment. While commercial enclosures do exist, most of them are quite expensive because shipping bulky items isn't cheap. That's why I'm going to show you how to build your own shell over the weekend with very few tools.

https://www.atom-stack.com/blogs/news/plastic-laser-cutting-and-engraving-machines

https://www.atom-stack.com/blogs/news/a-protective-cover-for-laser-engraving